Bootstrap activities in Japan Tatsuya Uyetani. 1.* - unedited transcript - Thank you very much for inviting me here today. It is a pleasure for me. Great work on the series of sessions that you are doing, in the past and advance. Another one, unfinished liberation. I think Doug is working, so I am working with him. Someone mentioned the notorious Californian DMV. I lived here three years from 94. My wife passed the test. She got the paper as you know. She had to renew her paper five times, and then one year later she got her license. This a different country I thought. In Japan, the train runs every six minutes with out a delay of a second. So, our countries are working at a different time basis. That is some difference between the countries. I started my career as a computer engineer long time ago in the late 60's. We designed the computers. You may know or not. 1k for memory 4k drive, 8''and 6' height. The other day, we talked to all the people and friends we used transistor and so on to create those cabinets. I forgot what I said in the past. But my friend said you said is that will be my lunch box computer in the future. Did I say it? Yes, you did, he said. I asked my wife please find my lunch box. I will show you my lunch box. This is the size of what I said in the mid sixties. If I am fancy enough like al and Kay maybe I am famous. This is original one, the aluminum. The new one is plastic. So this size, this thick. This portion is filled with the rice. This portion is filled with assorted vegetables, sometimes meat or fish. My kids generation is different, the grow taller than me. This is a kind of joke, I think that the world is changing and revolutions are coming up every second. So, I remember the Doug as he started FDAC in 68, I got a copy of his paper in late 69. At that time, I couldn't understand what he mentioned. It is very sophisticated. In a quarter of a century as he mentioned we get together in Tokyo. He explained about bootstrapping alliance. It is so hard to understand. It is so hard to understand especially with a beer. I had to say something so I talked about our (TQC) total quality management. What we did in the past. Which is under generation can propose his own idea to the senior management. Like a small piece of the venture. I felt something. I did not' fully understand. But any way he asked me to join the bootstrap alliance. So I did. Any way one item he said, Collective IQ. It is quite familiar with us. Brush up on the IQ for the university. IQ is a very strong. I am very much interested therefore; we should start something in Japan. Then we started the seminar with Doug. Then a number of people get together and start to think about what he mentioned. So, I think as what is the best way to implement bootstrapping or a NIC. If we are explaining bootstrapping itself or a NIC it is really tough. So, start with an argument. So, we can do that. One thing I started with JMBA, which is the member of the manufacture of the facts. So, every year or every other year they make some kind of proposal or some standardization. I was called in late '68 coincidentally near Doug's meeting. They asked me to chair some committees. Created by Japanese people. Mostly they are standards coming form the U.S., and we will use them and implement them. So, the beginning was only twenty people. I didn't know most people. So I thought what shall we do. Now it is a hundred and fifty people working together. We are now providing some solutions that will of May this year. So, I will talk some details. I don't want to touch this itself but mostly the operating system come from the U.S.

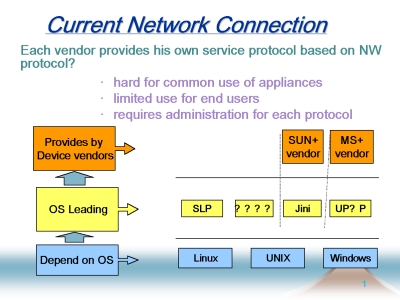

Those are also coming from the U.S. and then our vendor is working to come on our printers or fax to check with functions. Every time you use something, we have to work on that. And every company does not help each other. If we introduce a product, they do not talk to each other. That is a big problem in Japan. We are Japanese manufacturing our product maybe seventy percent worldwide. Therefore, my proposal is we do not want to change the proportion, we will upset everything.

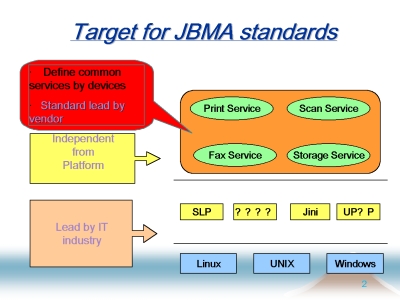

However, what kind of standard, what kind of functions are these. We should have talked and talked, so we have defined the commons services by devices. If we can meet this context, then we can talk wherever we go. If I bring the PC here, I want to read a doc, I will find out any print out. Rather than someone asks, I have to ask please print this paper and song. So, that kind of thing is ongoing. We are working on these areas.

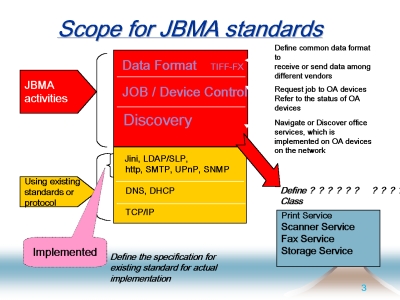

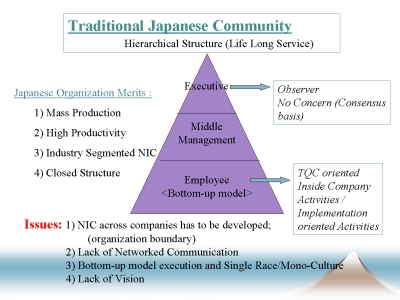

Discovery of all of the printers and papers and so on. Data format, job device control those are maybe 70, 80% achieved. All of the companies bring their papers. This is a very in Japan. It used to be each company has its own idea, they do not disclose their ideas, but NIC solved the problem. This is very difficult technology side. I think that those kinds of ideas can be diversified. So, we think of traditional Japanese community as a hierarchical structure. Life long services.

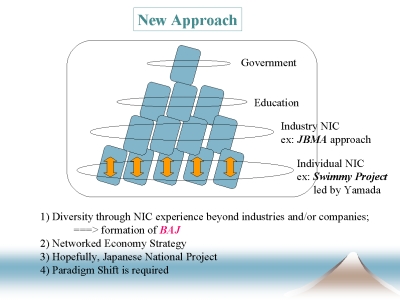

To the top we sit together for over thirty-forty years. We don't make any documents, but understand each other. Same culture, meeting at the same time, everything. One example, a cooking book, big diverse between countries. UK cookbook they outline every statement. Sentence. Japanese. Just pictures. One spoon two spoons. We have the same culture so we understand each other, what we should do. But Americans in the middle. Those kinds of knowledge has to be implemented now that we change our organizations. Then mostly and inside company structures and then the bottom up. The seniority just observing the activities of those people. Sometimes no concern, mostly they are consensus basis. They fully understand the meaning of each. Therefore, our organization strong lists those in mass productions. Making the product. Even thought we don't give up any visions and so on. But, we decided what we should make it is very strong. Then one culture we decided does the high productivity. We can do some NIC because we are doing the TQC as you can see. But those NICS are industry segmented. The iron steel manufacturer has his own and automobile has his own and they don't communicate to each other. Across stretches, we don't dictate. Because of the human being long life. Therefore, we have to change some paradigm. One is NIC across the companies. It as to be developed based on we have to erase the organization boundaries or company boundaries. We still lack the network communications. Now as the Japanese telephone company providing I-mode which using telephone for communication, just pushing the thumb to send the mail, it is a Japanese trick. Rather than pushing the keyboard. Then bottom model execution and single race monoculture. Then lack of visions. Those kinds of things we have to think modernizing. About changing by bootstrapping.

The idea of JBMA is each company has one or two people, then after that,

each company after has ten or so. The divisions are from the printing divisions,

or copying divisions, or other divisions. They start at some correlation.

NIC that is the correlation. We have ten companies each has his own

NIC. We have a JBMA NIC now. We are talking to each other beyond the companies.

This is the first time. So all the document is open source for membership.

So, we are going to open up around the May time frame. We are going to

do our demo at the business show in Tokyo. After that we are going

to do that. But still this is little. Not going to world wide and so on.

How to bring this idea to other countries. And we are thinking about that.

I think that these actives can and will be done in Japan very soon.

Still, we have a bunch of problems of government structures, education

and so on. So, I think this little we have to change our paradigm.

That bootstrapping in Japan would be one of the drivers for changing community.

The network economy will be implemented very soon. Then we hope to

bring this idea in to the Japanese government national project. It takes

time. I think it is a small project that is started. This is the

kind of the softer houses get together but the small softer houses are

implement but they don't have enough sales force. So those are the

cases we provide with a common database or repository so that they can

access from the outside. Those are started. Currently the only few example

that we could have

In the past, we have been trying to deliver "less expensive and better quality" products through TQC cultivated within a company or NIC-like activities seen in some industries as value added implementation. Now we feel it is important change our company attitude and also working global, to have an organization to cope with the world wide issues, as discussed in this colloquium by linking coordination a wide variety of existing and emerging NICs ranging from individual to the nation levels. We think this linking process is "Scaling" Thank you very much.

---

Above space serves to put hyperlinked

targets at the top of the window

|

Fig. 1

Fig. 1 Fig. 2

Fig. 2 Fig. 3

Fig. 3 Fig. 4

Fig. 4 Fig. 5

Fig. 5